KEEPMOAT has adopted a JCB digital tool to cut carbon emissions across all of its live construction sites nationwide.

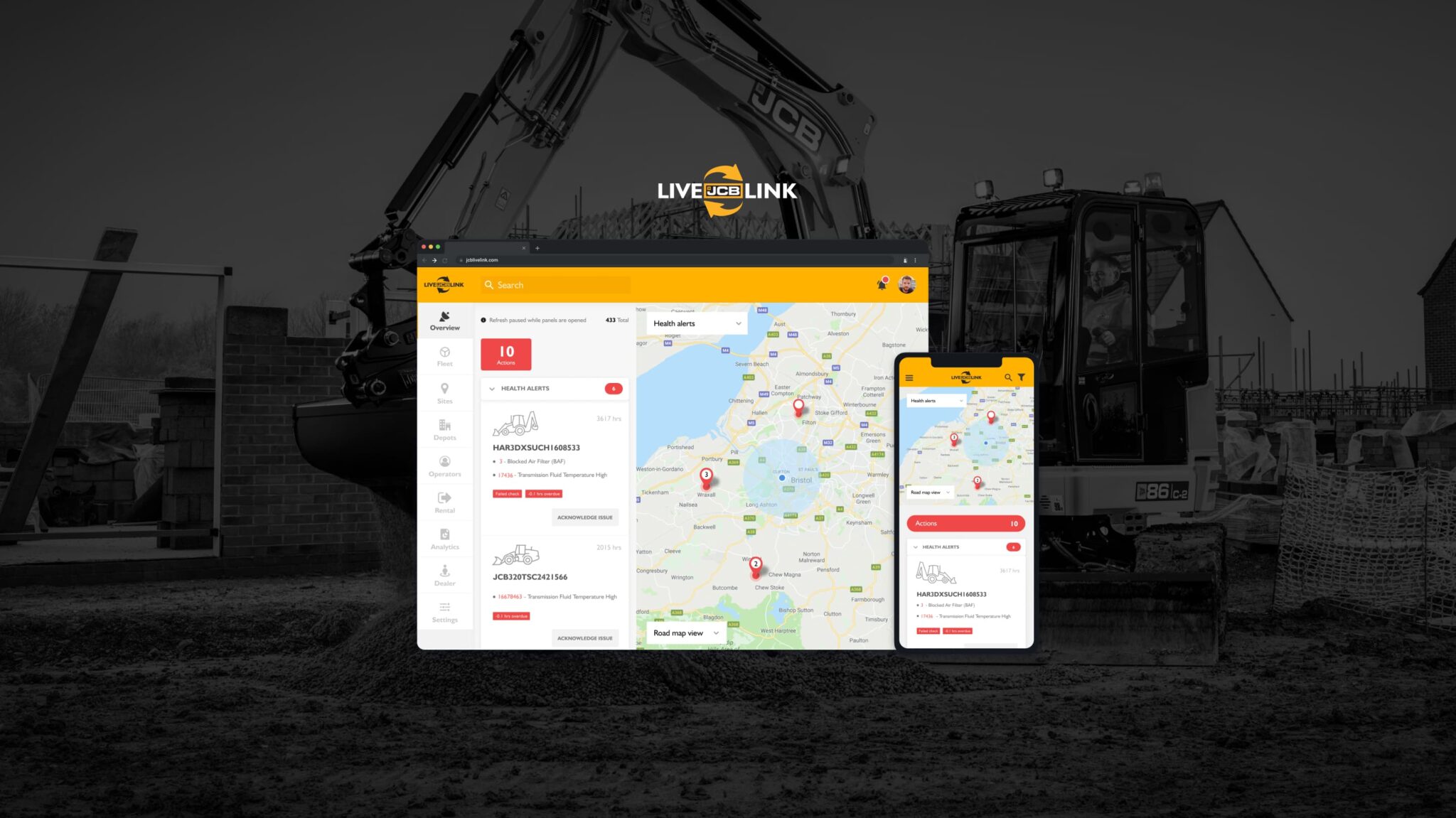

The housebuilder will deploy JCB’s LiveLink fleet monitoring software, which provides visibility of machinery across the site through a single, central dashboard.

By tracking idle time, fuel consumption, and machine movements, the system is designed to enable operational teams to reduce waste, optimise fleet performance, and improve efficiency.

John Bowden, sustainability director at Keepmoat, explains, “We’re thrilled to work with JCB and access this fantastic software. At Keepmoat we’re focused on driving sustainability and efficiency across every stage of the construction process – from design and material selection to on-site operations.

“By bringing all site data together on JCB LiveLink, we have a single, standardised platform to provide the visibility we need to identify inefficiencies, drive behavioural change and make informed decisions that directly support our carbon reduction goals.”

Launched in 2012, JCB LiveLink integrates GPS data, telematics, and machine usage metrics to provide monitoring and insights.

Jude Qureshi, general manager for JCB LiveLink, added, “JCB LiveLink delivers a powerful, cost-effective solution that empowers the construction industry to actively monitor and optimise fuel consumption – an essential foundation for any effective carbon reduction strategy. With detailed insights and actionable data, LiveLink enables construction professionals to make informed decisions that drive efficiency and sustainability across their operations.

“Some plant hire companies are challenged by utilising multiple reporting systems, which often leads to fragmented data and difficulties in achieving a unified perspective on equipment efficiency. Keepmoat investing in one solution for all their fleet is a true commitment to their carbon reduction goals.

“It has been a privilege to partner with Keepmoat and support the onboarding of their suppliers to Livelink, which enables the team to regularly review their machine data and performance.”