From humble beginnings, tiltrotator manufacturer Steelwrist has grown into a global powerhouse. To celebrate the company’s 20th anniversary, CEO Stefan Stockhaus answered Project Plant’s questions about the journey so far and plans for continued expansion

Q) Why was Steelwrist founded? What was the initial aim of the business and what were the early days like?

A) Our founders Stefan Stockhaus and Markus Nilsson were looking to build a company with its own product, including R&D, manufacturing and aftermarket, all under one unique brand. During the process looking at different companies and products they came across the tiltrotator, a product used in a few Nordic markets and with only two major competitors. It was clear that there would be room for one more player. Steelwrist focused on growing globally from the start, not only looking at the Nordic markets.

During the first years it was hard work, both day and night. If the team was not sleeping, they were working. Often the team worked in the office during the day and then during evenings they assembled tiltrotators and quick couplers. Everyone helped with all tasks and that same spirit of always helping each other remains deeply rooted in Steelwrist also 20 years later.

Q) What were the first products you launched and how did the market respond at that time?

A) The very first products launched was the Steelwrist X18 tiltrotator. It was joined by the X06, X12 and X26. This meant that early on Steelwrist had a product portfolio of tiltrotators that covered excavators from 4 to 26 tons.

Q) When did Steelwrist enter the UK market for the first team?

A) The UK market came in focus for Steelwrist in the early years and presence with a local team was established already in 2008.

Q) Would it be fair to say that Scottish contractors were amongst the most enthusiastic early adopters of tiltrotators?

A) Yes. In Scotland you see many smaller contractors and owner operators, and these operators are typically early adopters of new technologies. An excavator equipped with a tiltrotator typically becomes 20-40% more efficient and you as an operator become more flexible and can perform new tasks with your machine. All this has a direct effect on the possibility to earn more money on your investment.

Q) What have been some of the key milestones and memorable moments over the years?

A) Of course, the first launch of the four tiltrotators models X06, X12, X18 and X26 is something to remember and then we have the very first customer that took delivery of a X18 tiltrotator in the first months of 2006 – a key milestone in our company’s history. If you then look at our 20-year timeline the list of memories and key achievements is very long, but there are some that stand out from a product perspective.

In 2009, we launched our first own tiltrotator control system, XControl. We already from the start understood that the control system is a critical part of a well-functioning tiltrotator installation.

Then in 2012, we launched our front-pin-lock (FPL) technology for tiltrotators and quick couplers. The Front Pin Lock safety system is a patented mechanical solution that locks the front pin of the work tool, safety has always been in focus within Steelwrist.

Moving on to 2017, we launched our range of automatic quick couplers which we call the Steelwrist SQ auto connection system. An excavator equipped with a SQ coupler means that the change of hydraulically powered work tools can be made in seconds, all with the operator having to leave the cab.

Following our launch of the SQ technology we co-founded the Open-S standard in 2020, with the ambition to create a global open standard for automatic couplers. Since we initiated this work the number of Open-S members has grown rapidly and we now have close to 20 member companies in North America, Europe and Asia, all with the common goal to grow this global standard.

Finally, we come to 2025 and the launch of SQ40 which means we brought the automatic coupler technology compact excavators from below 6 ton. With SQ40 we have a range of automatic couplers for excavators from 2 to 75 ton.

Q) How would you sum up Steelwrist today in terms of the company’s impact around the world?

A) Growing from a small workshop north of Stockholm we today have team members in more than 20 countries in the world. A great global team that is working closely together sharing a common goal to make excavators more efficient. When we started the tiltrotator was very much a Nordic product with high utilisation in these countries, but outside this area the product was still unknown. That is not the case today, with our expansion and thanks to the increased use of social media more an more excavator operators are finding their way to the tiltrotator, and the interest just keeps growing.

Q) How important have partnerships and a thriving dealer network been in the firm’s success?

A) Very important! We work exclusively with excavator dealers around the world and a close cooperation with all dealers is crucial to our success. We believe strongly in being the best partner to our dealers and we develop tools and solutions to help these dealers successfully promote, sell and support our wide range of Steelwrist products.

Q) How do you stand out in a competitive market? How would you define the company’s culture?

A) Our core values of Responsiveness, Simplicity and Speed guide the way we work with customers, dealers, suppliers and employees. We are today a large global organisation, but still when you meet Steelwrist team members anywhere in the world you will experience a team that is truly easy to work with. There is a collaborative approach in our company that really sets us apart from competition.

Q) What are some of the latest products and innovations?

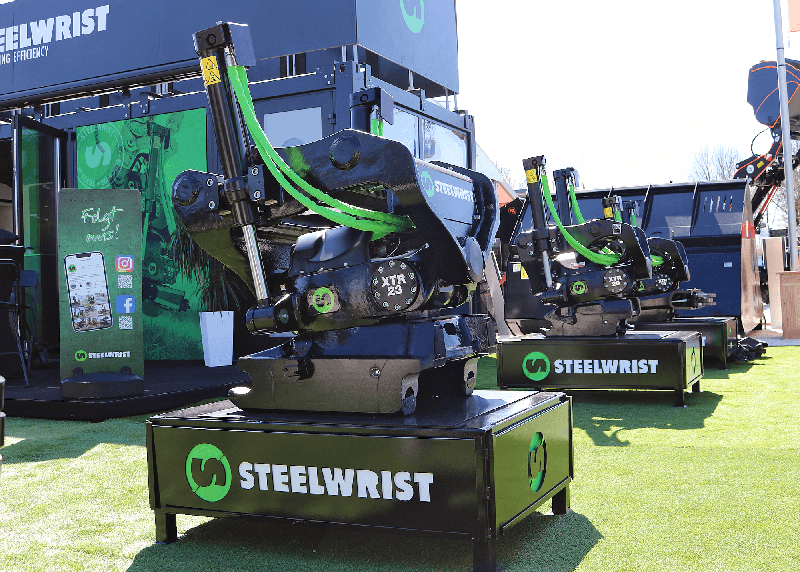

A) In 2024 we launched the first model in our 3rd generation tiltrotators – the XTR20. We have continued to launch additional models in this 3rd generation of tiltrotators showing XTR15 and XTR23 during the bauma exhibition in April this year. Our 3rd generation tiltrotators are brand new and all our experience from 20 years in the industry has gone into this new generation.

At bauma we also launched one of our biggest news to date when we introduced the SQ40 (patent pending), extending our automatic oil connection technology to compact excavators. In SQ40 we have an innovative design of the couplings that enables high flow capabilities making it possible to achieve a flow of 70 l/min. This enables the excavator to run demanding hydraulic work tools and you can change hydraulic work tools without leaving the cab.

At the same time, we launched a wide range of powered work tools like grapples, compactors and the new Tree shear all with SQ40 interface.

Q) What are some of the biggest changes you’ve seen in the industry over the past 20 years?

A) If you look at excavators there are clearly three things that have grown in importance over the last 20 years: that is MCS (Machine Control Systems), automatic quick coupler with integrated hydraulics and tiltrotators. So, two out of these three products are part of the Steelwrist portfolio, so it is safe to say that we are in a key part of our industry.

Then the growth of social media and that information is just one click away online has of course meant that knowledge about our products and solutions is today instantly available to anyone anywhere in the world. This was not the case when Steelwrist was born just 20 years ago.

Q) What did you do to mark the 20th anniversary?

A) We kicked off the year creating a special 20th year anniversary logo, which has been part of all our communication and marketing throughout the year. Then we invited almost 500 people to our headquarters north of Stockholm to a large celebration during three days in May. We had guests coming in from all over the world, some came all the way from USA, Canada, China and Japan, and of course we had a long list of guests from several European countries.

During the event we had a large exhibition with our complete product range on display at our factory and we also organised a highly appreciated tour through our production. Then we ended the evening at a nice venue with good food, entertainment and speech from our CEO, Stefan Stockhaus.

In conjunction with the celebration in May we also released a 20 years anniversary movie which we welcome everyone to watch on our YouTube channel.

Q) What can you tell us about future plans?

A) We continue to grow the Open-S standard for automatic couplers. During 2024 we saw the number of members double and right now discussions are ongoing with several new members, and it won’t be long until the organisation has more than 25 members.

From a business perspective we continue to focus on our global expansion growing our local country organisation in all parts of the world, all this driven by the increased demand for our Steelwrist products and solutions.

Finally, from a product perspective, we are continuing the roll-out of our 3rd generation tiltrotators. Four models are already available, and more are on the way, which will be launched before the end of 2025. With the roll out of the 3rd generation we introduce several major IP protected innovations that will consolidate our leading position further.