Quvo Ltd is the exclusive partner for OwlEye LiDAR technologies in the waste, recycling and aggregates industries in the UK and Ireland. The tech offers 24/7 volumetric measurement solutions. Project Plant recently attended Quvo’s open day at Cireco Scotland’s Dunfermline base and spoke to co-founder – plant sector stalwart Allan Kane – about the venture.

Q) What’s the history of Quvo?

A) Around 18 months ago, my brother Ross and I decided to set up Quvo to look at using technology to help businesses more accurately mange their stockpiles. The lack of actual data across many sectors including waste management, bulk handling and aggregate processing was a real surprise, so we sought to find solutions to this problem.

Additionally there is a real focus in the business world towards digitisation and the LiDAR solutions we provide can play a key role in businesses achieving this objective.

Q) How does the Sachtleben OwlEye LiDAR technology work?

A) Basically the LiDAR technology allows customers to have 24/7 on demand data of their stockpile inventories. Once installed, the LiDARs are constantly taking readings which are then visible by the client in the form of actionable data.

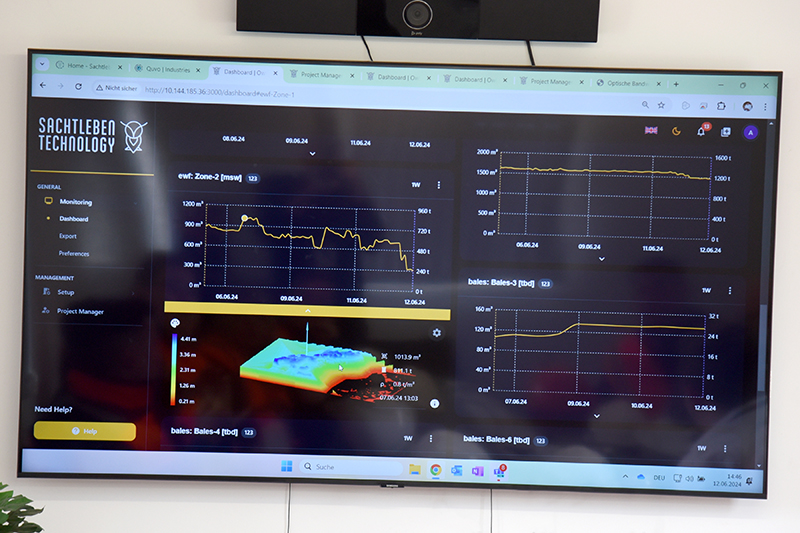

Depending on the clients’ needs, this can be integrated into their existing operating systems and/or displayed in our own dashboard solution. The dashboard is fabulous and allows instant management of stock levels, historic trends, 3D display of the actual stock areas and can be set up to send auto alerts based on individual operational needs such as minimum or maximum stock levels.

The LiDARS can be used remotely to view remote sites or other sites within the business from a central point or on a phone/tablet.

Currently our LiDAR solutions are being used to benefit many clients including Cireco, NWH and Levenseat.

Q) Was there a gap in the market for this kind of service?

A) Absolutely. Currently, there are two solutions for clients, the first being the human eye and the second being topographic reports via drones.

In terms of the human eye, this judgment can vary between individuals based on experience or motive. It is also challenging once the volume being measured increasea to beyond a few loads (often how clients judge their volumes) and is in no way scientific or exact.

Similarly, the use of drones for such measurements has limitations in the form of cost, practicality and also the fact that as soon as the drone lands, the information is out of date. Often in such environments material is moving constantly, meaning the data being analysed is therefore historical. In terms of the LiDAR solution, this provides constant live data once the cameras are mounted, so data is then available on demand to make informed management decisions in real time.

Q) What are the potential advantages for the material processing or bulk handling sectors?

A) The key advantage is being able to manage operations on actual real time data at the click of a button. This data can then help with operational decision making in areas such as inventory management, logistics, stock movements, preventing stock outs and analysing true production.

Another key benefit of our LiDAR solution is for accounting purposes where key measurements such as month end inventories for accruals or liabilities can be accurately measured. Wider business benefits can be seen around compliance and insurance where thresholds can be monitored and proved to be within limits.

Q) Are there opportunities for clients to help shape the innovation?

A) This is a key USP for us at Quvo as all our clients have specific individual problems which we are looking to resolve using our solutions.

With all our clients, we listen to their challenges and have made tweaks to give them the exact output they require. The beauty of the software is it can be tailored to their needs to ensure maximum impact on their business.

Client feedback is critical to ourselves and our partners OwlEye as this allows us to keep pushing the boundaries of the technology and the dashboard capabilities. An example of this in the early days was setting up auto email alerts for a client on maximum tonnage levels to prevent them exceeding levels onsite. Another example was setting up a simple visual with a truck so that a remotely based logistics team could see how many truck loads were lying to be moved from site.

Q) What are your plans for future growth? Do you see huge expansion potential?

A) Yes, absolutely. It’s like any tech product; it can take people time to understand it as it’s completely new. I feel with the regulatory push towards digital waste tracking, solutions such as our LiDAR-based volumetric measuring will play a key part in this to drive accuracies.

As for Quvo, we have already added an exceptional partner in H-Sensortechnik who are market leaders in optical belt scales. This product fits nicely in our portfolio as it enables customers to accurately measure material flow in their processing equipment such as MRFs, crusher and wash plants. Our aim is to provide clients with the very best technology in order to aid their management of materials, we will always have an eye on new technology and software that we can add to our offering.

Q) What was the feedback from the open day event at Cireco?

A) Absolutely brilliant. Seeing really is believing when it comes to this technology.

At the open day we managed to showcase our new optical belt scales working and three live working LiDAR setups. We were able to show the data on the phone and in the boardroom so the visitors could appreciate the level of data available to them. We’ve a busy few months ahead scoping new projects and installing solutions for many of the visitors.