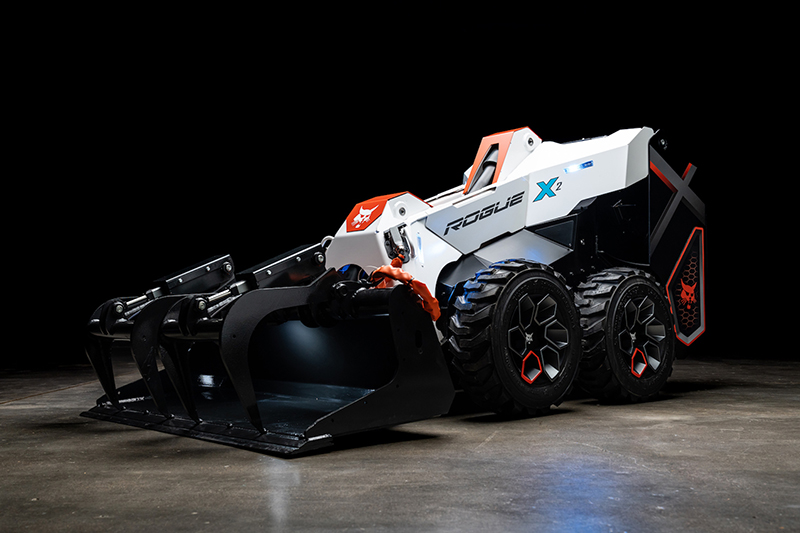

BOBCAT has revealed that its stand at Intermat 2024 will give an insight into what the company is developing for the construction industry of the future, including the unveiling of the new RogueX2 autonomous loader concept – the second iteration of the original RogueX system.

Other new additions being showcased at Intermat include a range of rotary telehandlers and a new variable pressure portable air compressor.

The RogueX2 loader has been developed from the RogueX concept presented at the Conexpo show in Las Vegas nearly a year ago. RogueX2 is an all-electric and autonomous concept machine that produces zero emissions, and features a lithium-ion battery, electric drive system and electric actuated lift and tilt kinematics with no hydraulics.

Designed and built without a cab, the RogueX2 and RogueX concept machines address the challenges of labour shortages by eliminating the need for an operator. They also provide the blueprint for how work machines of the future can be designed and optimised for new technologies.

In RogueX2, the internal combustion engine (ICE) is replaced with an electric powertrain for power and drive. This machine also eliminates 100% of the hydraulics, including all connectors, hoses, tubelines and fittings that Bobcat said are common failure points. The absence of hydraulics and fluids in its design reduces ICE emissions, noise pollution and the risk of all environmental pollution.

The original RogueX was designed with tracks. RogueX2 is designed with wheels to optimise the electric battery run time. It also features axial flux motors, which Bobcat claimed give the machine ‘incredible’ tractive effort.

Together, the RogueX and RogueX2 concept loaders have garnered many new patents pending. “These patents represent more than new features on a machine – they signify how we are breaking rules to define a new work experience,” explained Joel Honeyman, Doosan Bobcat VP of global innovation.

Bobcat will be showing a new range of rotary telehandlers for the first time at Intermat. The range offers nine Stage V-powered models for the European market (for lifting heights from 18 to 39m) and four Stage IIIA-machines for sale in the Middle East and Africa (covering lifting heights from 18 to 26m).

The models with lifting heights from 18 to 26m are Deutz engine-powered, with the higher lift models from 26 to 39m powered by Volvo engines. The same manufacturers are common to both the Stage IIIA and Stage V models.

One of the key features is the patented panoramic cab.

This year will also mark the first time visitors to Intermat will see the new Bobcat range of portable power products. The manufacturer will be debuting the new PA12.7V portable air compressor. This is a variable pressure compressor, that utilises a system called FlexAir technology, allowing it to operate in the range of 5.5 to 12.1 bar and offer free air deliveries from 5.2 to 7 m3/min.