WET processing solutions specialist CDE has launched the AquaCycle A2500 thickener, the latest addition to the firm’s water management and recycling systems.

With a capacity of 2500m³/hour, the product is described as CDE’s ‘largest and most advanced’ water management system to date.

CDE explained it has been developed due to demand from materials processors in high tonnage markets for water management solutions equipped to supply operations with sufficient water supplies while ensuring optimal production efficiency, minimum loss of fines and maximum water recycling.

Darren Eastwood, strategic development director at CDE, said, “It is increasingly important for materials processors to invest in an effective water management system that ensures a steady supply of clean water to their plants through cost-effective means.

“The continued advancement of our pioneering wet processing solutions and leading-edge water management systems is supporting operators working in the natural processing and waste recycling sectors worldwide to overcome the challenges of washing in water-pressured or water scarce areas today.”

CDE added that where it ‘bridged the gap’ in 2018 with the launch of its A900 and A1500, providing a median alternative to its 600m³/hour and 1500m³/hour models, the new A2500 expands the range to fit the requirements of sites processing high tonnages.

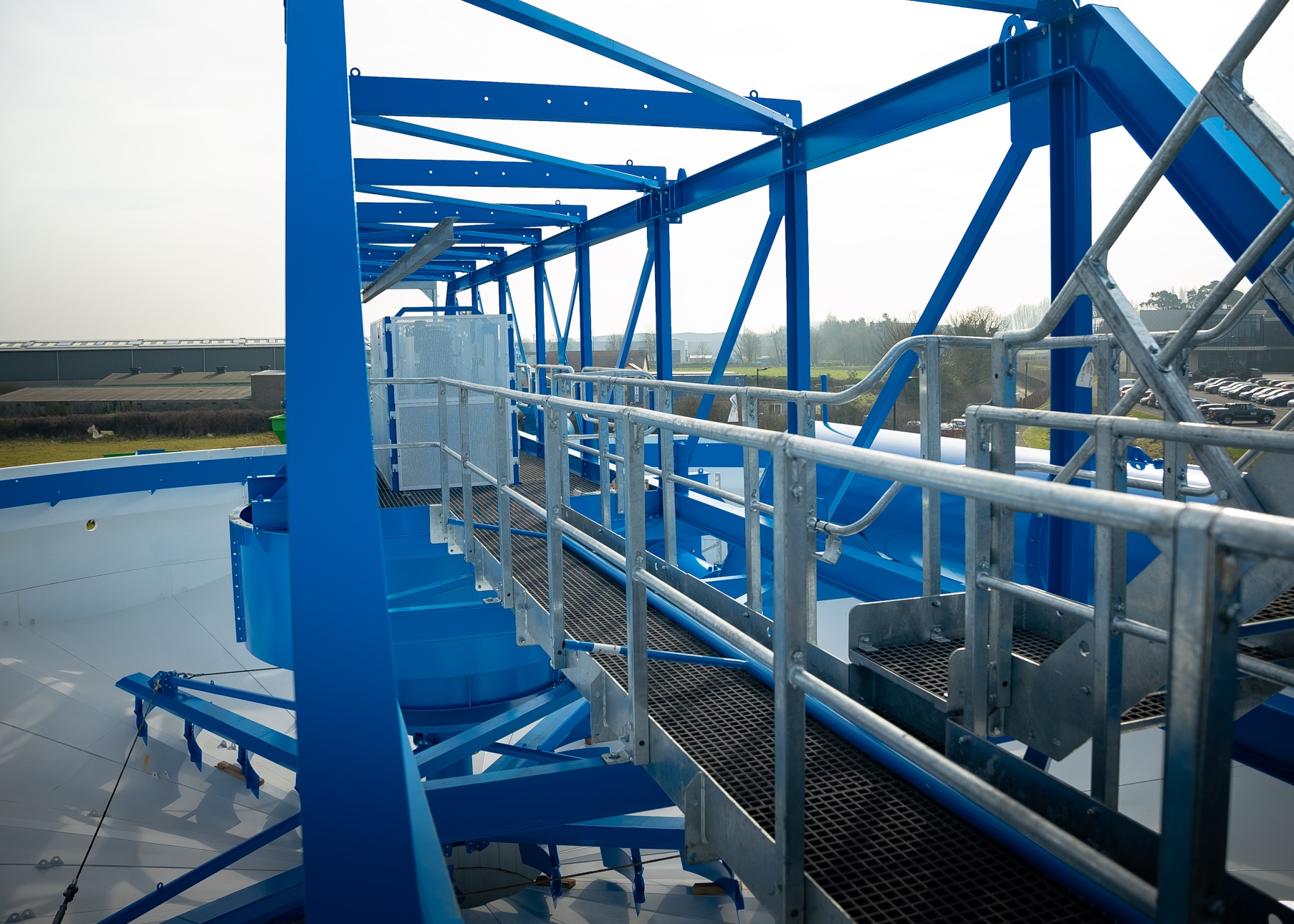

The solution boasts the first lattice bridge structure on any CDE thickener. An integrated monorail also provides access to the motorised rake, gearbox and motor.

With a sludge capacity of 125 tonnes/hour, the A2500 includes an adjustable rake lifting mechanism. Featuring passive torque control, the automatic raise and start sequence is designed to protect rakes from surge pressure from dense sludges.

Another feature is the feed height. Sitting at almost 6.7 metres, the A2500 is said to simplify upstream plant design complexity as it eliminates the need for expensive civils.

Darren added that the development delivers all the benefits of CDE’s existing AquaCycle range on a much larger scale.

“It responds directly to the needs of materials processors operating in high tonnage markets,” he stated. “These operations, primarily in the areas of C&D waste, specialist sands and heavily clay-bound aggregates, require higher volumes of water resources; they need flexible water management systems with the capacity to supply their operations without compromising on footprint; and they need a system that can deliver this in a way that improves efficiency, driving down operational costs to maximise profitability and enable fast return on investment.

“These are the guiding principles that underscore the design and development of the new A2500.”