THE team behind the HAAS TYRON slow-speed shredder has converted the machine into a hybrid model, as part of efforts to become more environmentally friendly.

The transition to electric and alternative fuels has broad support, but has been put under time-pressure by the removal of the UK red diesel subsidy, according to CRJ Services.

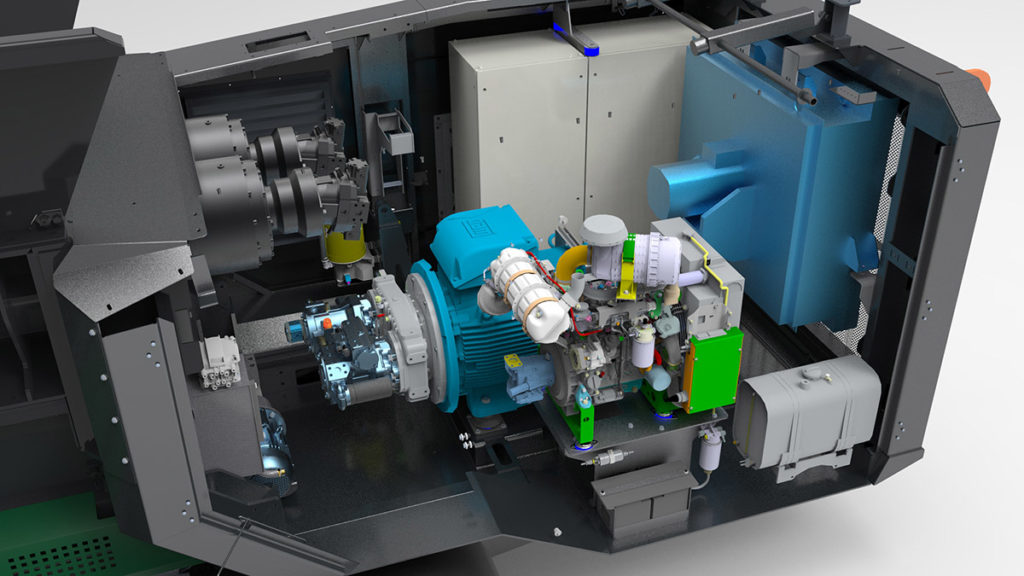

The new Hybrid TYRON ‘bridges this gap’ by combining a small 43kW diesel engine with a 280kW electric motor. The diesel engine is used exclusively for operating the tracks to manoeuvre the machine around a site, while the electric motor provides power to the rest of the machine, including the shredding shafts themselves.

CRJ explained the new solution combines the flexibility of a mobile machine with the energy efficiency of static equipment. It reduces the reliance on diesel and produces no exhaust emissions during operation. The Hybrid machine is also said to offer quick set-up times, with a three-phase connection to the mains, a multifunctional control panel, and remote control.

The Hybrid TYRON includes all the features of the standard TYRON 2.0. The recently upgraded shredding chamber is described as providing a more ‘aggressive’ infeed and optimal clearance between the shafts and the outfeed belt, increasing throughput capabilities.

The Hybrid TYRON also incorporates the upgraded servicing and maintenance features of the TYRON 2.0, including ground level access to the shredder chamber.

Ben McQuaid, director at CRJ Services, said, “The introduction of the Hybrid HAAS TYRON provides our customers with the flexibility of a mobile shredder, whilst benefiting from the efficiency and power of a static electric machine. Needless to say, this is something that has become increasingly important with the scrapping of the red diesel subsidy for the UK waste and recycling industries.”

Rene Perne, sales manager at HAAS Recycling Systems, added, “Climate protection and CO2 reduction are elementary challenges of our time. The new hybrid version of the primary shredder is a mobile, electric version. This TYRON combines the convenience of a mobile machine with the energy efficiency of a stationary plant. The shredding process is emission-free. This saves a significant amount of CO2 and is our contribution to climate protection. We hope that our customers feel the same – and decide to switch from diesel to electric drive.”